What is carbon capture?

Carbon dioxide (CO2) emissions generated by human activities have led to an accumulation of greenhouse gases in the atmosphere that is causing an increase in

Carbon dioxide (CO2) emissions generated by human activities have led to an accumulation of greenhouse gases in the atmosphere that is causing an increase in the Earth’s temperature and thus climate change.

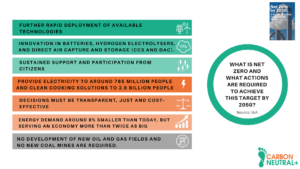

Carbon capture and storage (CCS) methods are being widely studied in the scientific field. Several scientific reports, such as the IEA report on Net Zero and the latest IPCC report (2023) have mentioned the need to implement CCS methods to reinforce current mitigation measures against climate change.

In this article we will tell you what carbon capture and storage is, and what are the advantages of this new technology. We will also review the current projects and industries that have already implemented this technology.

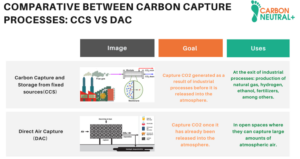

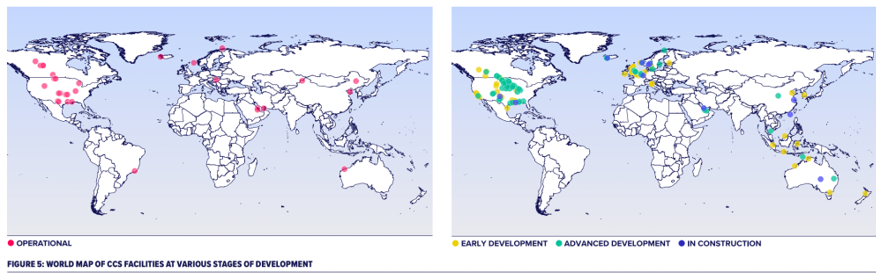

Carbon capture and storage, also known as CCS (carbon capture and storage), is a process that consists of capturing CO2 emitted by power plants and other industries.

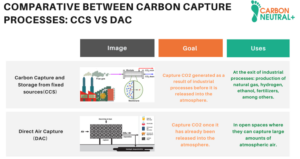

Carbon capture and storage methods seek to capture carbon dioxide (CO2) that is generated as a result of industrial processes (fossil fuel burning, steel production, natural gas, etc.) in such a way that these emissions are not released into the atmosphere.

In this way, the accumulation of these emissions in the atmosphere is prevented and thus its contribution to climate change is avoided.

This capture is followed by the transport and storage in deep underground reservoirs. CO2 can be captured, stored and transported in different ways, depending on the processes involved.

Carbon capture and storage is a three-stage process:

In the first stage, CO2 is captured from the emission source. These sources are found in different industrial processes that release CO2 as a product of some chemical reaction along the process.

Once captured, the CO2 is compressed and transported through pipelines or tanker trucks to the storage site.

In the second stage, the CO2 is transported from the emission source to the storage site.

CO2 can be transported in two different ways:

´

In the third stage, CO2 is stored in geological reservoirs deep underground that have no value to humans.

Geological reservoirs include salt formations, deep aquifers and depleted oil and gas fields. CO2 is injected into the reservoir and sealed to prevent leakage.

This is important because we must not untap these formations for any reason, otherwise there is a risk that all that CO2 will be released back into the atmosphere.

It can also be injected into formations rich in certain minerals which, over time, react chemically with the CO2 to give carbonates. This solves the leakage problem of the previous method, as the CO2 is converted to another compound through a chemical reaction.

Finally, CO2 can be used as a reagent in some processes. For example: carbonation of carbonated beverages, urea production, or methanol production.

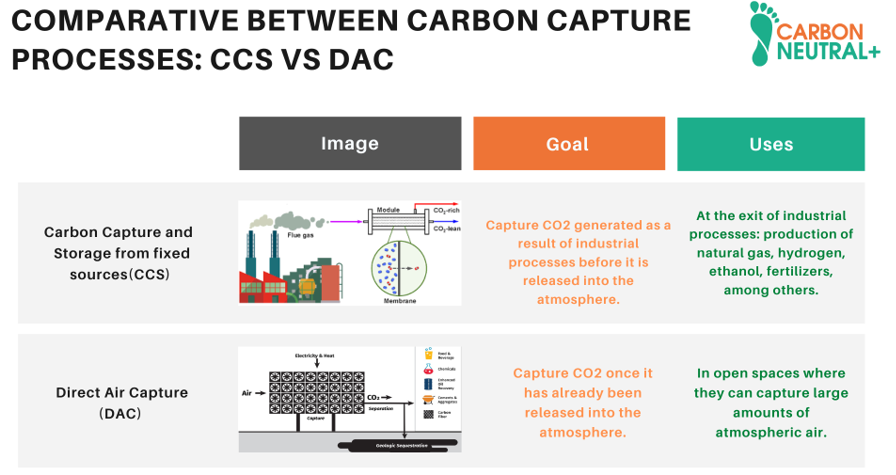

Carbon capture and storage methods are already operational worldwide.

According to the Global Carbon Capture and Storage Institute, as of 2023, there are a total of 30 plants operating with this system and a total of 196 plants under construction and development. Since 2021, the number of CCS projects has grown by 44%.

The image below shows the global distribution of CCS plants according to the latest report (2022) of the Global CCS Institute:

Industries currently using these methods operationally are (number of operational plants in each industry is shown in parentheses):

Other industries that are exploring CCS implementation due to the high CO2 emissions generated in their processes are:

The following is a list of the main industries that currently have CO2 capture and storage (CCS) plants in their facilities.

Natural gas is a compound consisting mainly of methane, extracted from fossil reserves. This fuel generally contains CO2 that must be removed before it can be marketed for domestic use (as cooking gas, for example).

The CO2 that is removed ends up being released into the atmosphere, so CO2 capture plants in these processes seek to prevent this from happening.

For these plants it is estimated that, if they are close to the fields where the CO2 will be injected, the cost of compressing, transporting and storing it is 15 to 20 dollars per ton of CO2.

The progress in the studies on CO2 processing at the exit of natural gas plants is very important due to the importance that this fuel has acquired in recent years as a “transition” fuel.

The iron and steel production industry is responsible for approximately 7% of global CO2 emissions.

In iron and steel production plants, CO2 is produced as a result of the chemical reaction of reducing iron ore to pig iron. Pig iron is the raw material used to make steel, and its production process involves burning coal in a blast furnace at high temperatures.

For this reason, among the technologies researched and implemented to reduce these emissions are CO2 capture methods such as CCS.

The use of hydrogen to obtain energy is one of the topics of the moment. When manufactured with renewable energies, the use of hydrogen does not generate greenhouse gas emissions.

One of the potential uses of hydrogen is car batteries, which would replace the use of fossil fuels for this purpose.

98% of the hydrogen produced today is manufactured from coal (gasification) and natural gas (methane reforming).

Both processes generate a large amount of CO2 emissions. These processes are compatible with CO2 capture processes (CCS). There are currently 2 operational CO2 capture hydrogen production plants in the world. Between them they have a production capacity of 600,000 tons of hydrogen per year.

Unlike CCS methods, these methods seek to capture CO2 from the atmosphere once it has already been released.

The operation of these methods is based on the fact that, through a fan, air flows into a structure containing chemicals capable of retaining CO2. This retained CO2 can then be stored or used for other purposes.

Once the CO2 is retained from the air stream, the “CO2-free” air is returned to the atmosphere. In general, it is not possible to completely clean the air but it is returned with lower CO2 concentrations than the initial air input.

An important advantage of these methods is that they avoid CO2 transport costs. These infrastructures are placed in strategic locations so that the CO2 obtained can be used for another process or stored in locations close to the capture facility.

The following image presents a comparison between the carbon capture methods mentioned in this article (CCS and CCS):

Carbon capture and storage currently faces significant challenges and limitations. Some of them are:

Carbon capture and storage is an important technology that can help reduce global CO2 emissions and combat climate change. This assertion is based on recently issued authoritative reports, such as those of the IEA and the IPCC.

Although it faces challenges and limitations, there are currently around 30 operational projects worldwide and more than 100 in the construction and development stage.

It is important to emphasize that, in the long term, further progress must be made in the transition to renewable energy sources and cleaner technologies. But carbon capture and storage can be a solution in the short and medium term.

Carbon dioxide (CO2) emissions generated by human activities have led to an accumulation of greenhouse gases in the atmosphere that is causing an increase in

According to the Emissions Gap Report 2022, the growth rate of global greenhouse gas (GHG) emissions has declined over the last decade. Between 2010 and

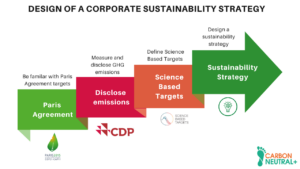

As international agreements related to corporate greenhouse gas emissions (GHG) come into force, the regulations associated with the generation of these emissions increase. This is

Climate change is one of the greatest concerns of our time. This phenomenon is generating consequences that are difficult to reverse, such as an increase

The Paris Agreement is an international agreement adopted on December 12, 2015 during the United Nations Climate Change Conference (COP21) in Paris, France. One of

As the world faces the looming effects of climate change, more and more companies are recognizing the importance of adopting sustainable strategies that aim to

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |